For the global supply chain, the hits just keep on coming. From the U.S.–China trade war to the COVID-19 pandemic to the war in Ukraine, unprecedented disruptions to the modern, worldwide flow of goods continue to provide a steady stream of challenges to the freight industry. The result has been an epic slowdown in the supply chain that impacts shippers, carriers, warehouses, and consumers alike.

In response, some companies overordered due to concerns about tariffs or scarcity of product for the past three years. The pandemic ordering behavior has driven warehouse prices up as capacity has contracted nearly every month since March of 2020, according to the Logistics Managers’ Index. Port traffic remains backed up to levels never before seen.

Related: How Cargo Spectre Dimensioners Keep International Freight Moving

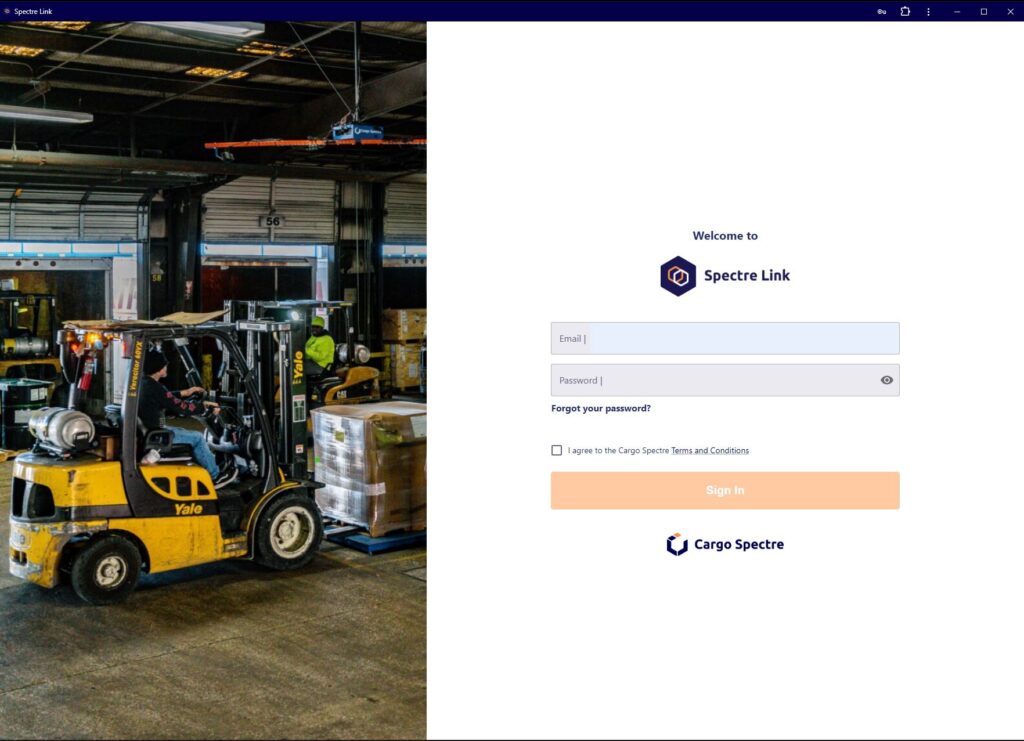

Wars and pandemics are obviously terrible things with consequences much more serious than continued supply chain disruptions. Nevertheless, these disruptions must be dealt with. Cargo Spectre seeks to lead the way by introducing a new and more affordable level of automation to supply-chain logistics.

By using automation to streamline operations and analytics to connect data end to end, our industry-leading dimensioning technology speeds up warehouse throughput dramatically. Automating manual tasks, such as pallet and parcel dimensioning, reduces errors, duplication, and rework to boost employee productivity. As a result, businesses can quickly respond to peaks and troughs in both supply and demand.

Cargo Spectre’s cutting-edge, machine-learning cubing and weighing equipment automatically collects and stores data that can be shared and analyzed in real time, closing the shipping loop across the supply chain. This automated data gives our clients the ability to move cargo without delays. Inaccurate data collected manually can lead to unnecessary slowdowns, audit fees, and hold times that cost time and money. Cargo Spectre eliminates these risks.

Part of supply-chain resilience is knowing that your carriers or shippers will move your freight without delays, fees, or fines. By instantly feeding cargo information into our clients’ databases of choice, this dimensional data can speed and improve processes from the beginning of the supply chain to the end.

Speed and accuracy are not the only advantages of automation, of course. Unlike your human employees, Cargo Spectre can run 24/7/365 without ever needing so much as a coffee break. Cargo Spectre never quits, never gets sick, and never goes on a vacation. It is always available for you.

Related: Meet the Dimensioner That Pays for Itself in 2 Months

Perhaps most critically, all Cargo Spectre system components and equipment are covered by a five-year warranty. If your scanning system needs repair or replacement, our technical team is always standing by to ensure that you experience the least amount of downtime possible at no additional cost to you. That means our automated dimensioning system will require zero maintenance costs and little to no downtime for at least the first five years of operation, even if you operate the system 24/7 with a high volume of freight.

If you’re ready to achieve new levels of efficiency up and down your supply chain, contact Cargo Spectre today. We help freight-industry partners around the world adapt to the new level of efficiency demanded by the marketplace!