Many first-time customers come to Cargo Spectre expecting to find 3D laser scanning technology capable of calculating freight dimensions. While laser scanning technology can be effective for pallet and parcel dimensioning, what Cargo Spectre offers is actually a more advanced scanning tech known as time of flight (ToF) scanning. What our customers quickly find is that ToF scanning offers many advantages over the laser scanning utilized by our competitors.

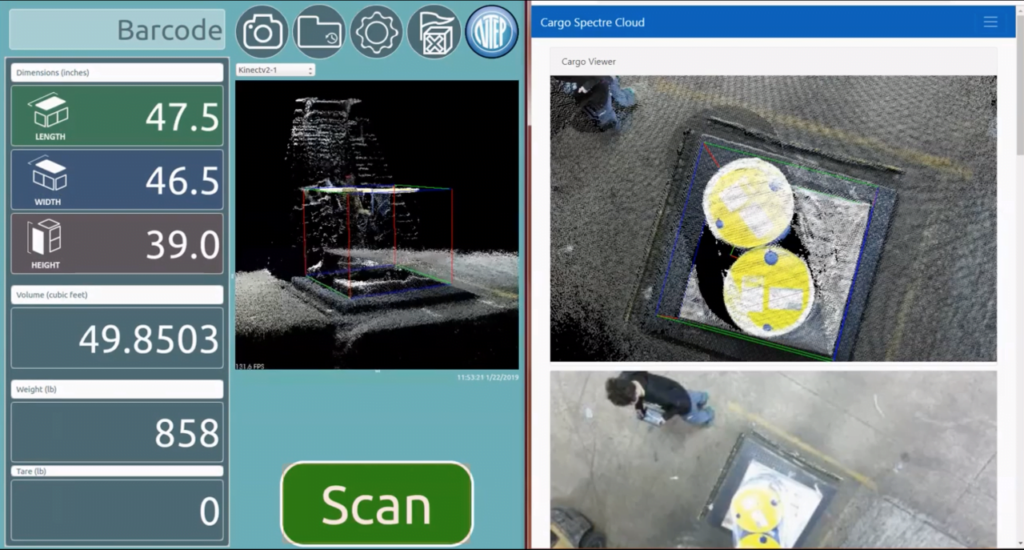

The differences between laser dimensioners and ToF dimensioners is pretty simple. Lasers, of course, are an older, more familiar technology that use single-point detection to measure distances, such as the depth of a parcel. A ToF camera, by contrast, uses infrared light to determine depth information. The sensor emits a light signal, which hits the subject (like a pallet or parcel) and returns to the sensor. The time it takes to bounce back is then measured and provides depth-mapping capabilities. This provides a huge advantage over other technologies such as lasers, as it can accurately measure multiple distances in a much larger area with a single light pulse.

One of the most important reasons that Cargo Spectre dimensioners use ToF instead of lasers is that laser devices must be calibrated to specific sizes and distances, requiring each machine to be specialized for different purposes. By contrast, time of flight devices like ours can scan a much larger area, allowing one device to fit multiple purposes and scan almost any object—even odd-shaped packages such as trees and plants!

There are many other advantages to ToF dimensioners when compared to laser dimensioners, however:

| Compare | Laser Dimensioners | ToF Dimensioners |

|---|---|---|

| 3D Quality | High-resolution, but susceptible to shiny or transparent surfaces | High-resolution, and handles shiny and transparent surfaces with no problem |

| Time | Take many minutes to scan | Take only 3 seconds to scan |

| Photos | Lasers cannot take photos. An additional camera is required for this feature. | Cargo Spectre records photo images and 3D point clouds at the same time. |

| Safety | Lasers can be harmful to eyes and are not OSHA-compliant. | ToF infrared light is safe and invisible to human eyes. |

| Support | Low investment into support and innovation from laser manufacturers | Industry-leading support |

| Cost | Expensive and specialized | Affordable and off-the-shelf |

If you’d like to measure how much faster, easier, and more completely Cargo Spectre ToF dimensioners can scan freight than our competitors’ laser dimensioning options, contact us today. We believe in our next-generation dimensioning technology, and we are happy to arrange a demonstration of its capabilities. Let’s get started!