The rapid rise of e-commerce shipping has made the application of dimensional weight pricing essential for LTL carriers. It’s a basic issue of density and efficiency. In 2013, major parcel carriers set the target density at nine pounds per cubic foot. In 2015, target density was increased to 10 pounds per cubic foot, and in 2016, it was raised again to 12. Every time the density factor is increased, light-density shipments are hit with a price hike.

Parcel carriers are simply attempting to apply true cost to their operations, incentivizing shippers to be more efficient. It doesn’t take a math degree to compute the fact that DIM weight impact has increased by 33% in the past six years. With this kind of aggressive cost increase, it is no wonder that parcel and LTL carriers the world over now recognize the importance of density on shipping efficiency. Fortunately, there’s a simple tool to solve this problem: Cargo Spectre’s automated dimensioner systems are an easy-to-use tool to measure density.

In addition to applying DIM weight pricing, Cargo Spectre’s automated systems can also be used to evaluate pricing accuracy and identify inefficient shippers. Both paths result in higher rates for companies shipping excess void. LTL shippers actually get a hit twice as hard on DIM weight, because pricing is based on both their ability to get good cube utilization on individual shipping cases as well as on their ability to stack boxes efficiently on a pallet. With Cargo Spectre’s machine-learning efficiency, loading voids, pallet overhang, and pallet underhang can now work to the carrier’s advantage in pricing.

Thanks to our advanced software, efficient packaging and pallet stacking can be rewarded with lower freight costs. LTL carriers who are Cargo Spectre customers can show shippers that packaging efficiency has direct correlation to transportation cost with easy-to-understand data.

The most profitable LTL and parcel carriers realized early that the application of dimensional weight has largely shifted the responsibility and the cost of inefficient packaging from the carrier to the shipper. Transportation cost is now based and invoiced on the freight class of the entire box and not just the product itself. While no formal announcement was ever made about this change in responsibility, it’s undeniably one of the biggest changes that has ever impacted freight classification.

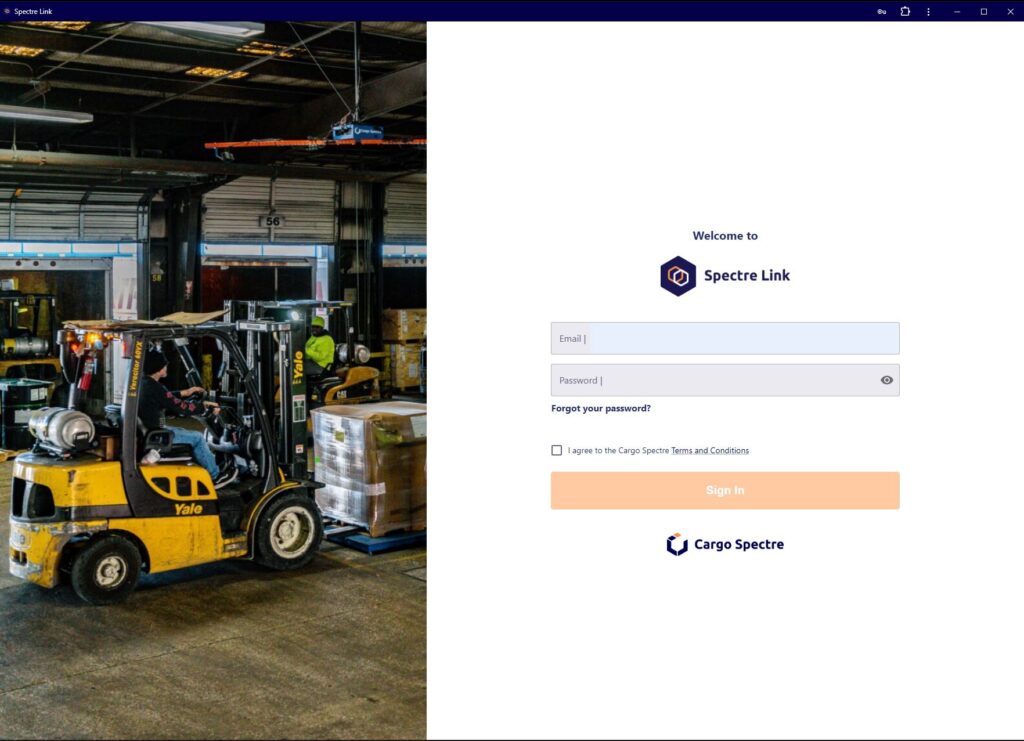

Cargo Spectre makes applying DIM weight to freight of all kinds fast, simple, and easy. It’s the most affordable dimensioning solution in the world: For only $500 a month, you can have a Cargo Spectre dimensioning system installed in your warehouse and integrated with your warehouse software of choice in just days. We offer a variety of scan triggering options so that your staff never even has to leave the forklift to rapidly weigh, photograph, and dimension and parcel or pallet.