How much can a single inch really cost you? If you haven’t done the math, you might be surprised. Pallet dimensions that are off just one inch from what’s stated on the paperwork can cost shippers and warehouses thousands of dollars, even if the pallet shifts or bulges after the initial measurement. How much money is your business throwing away every day on imperfect measurements?

Let’s find out!

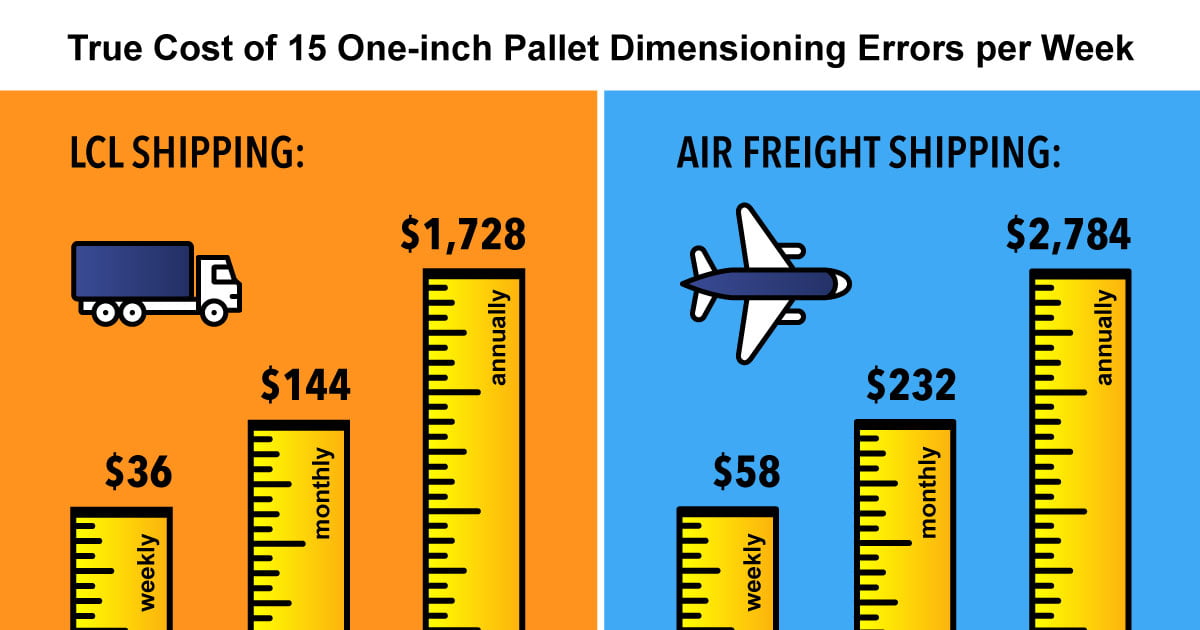

We’ll start with the cost of one, single inch in LCL and air shipment. That’s $1,728 for LCL shipments and $2,784 for air freight shipments. Here’s how we arrived at those figures:

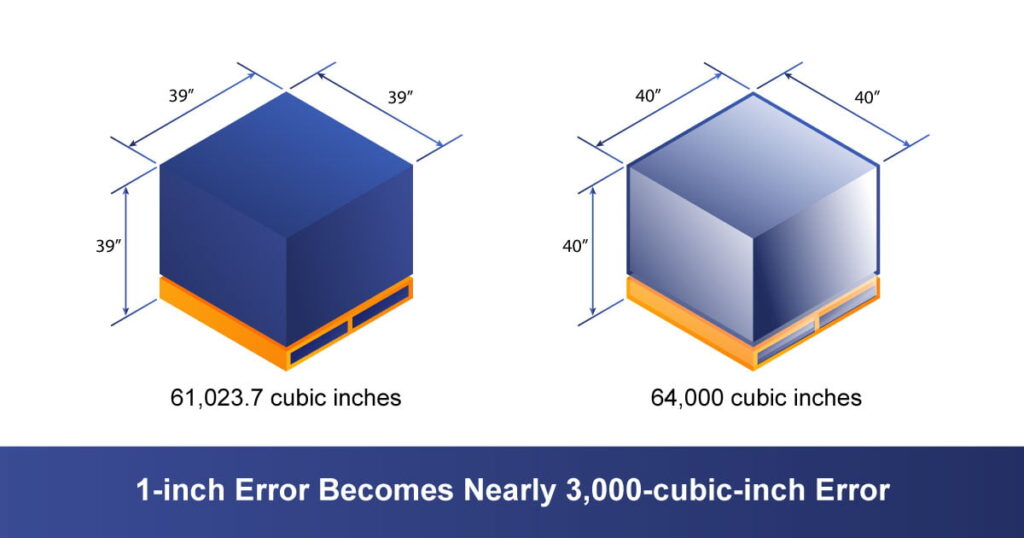

To ship a pallet that’s 1 m x 1 m x 1 m from Charleston, South Carolina to Rotterdam in the Netherlands costs $50 in LCL and $80 in air freight, assuming the weight to be constant at 50 kg. One meter converts to 39.37 inches. To make the math a little easier, let’s round down to 39 inches. That gives us a volume of one cubic meter equaling 61,023.7 cubic inches.

Anyone who has worked in logistics knows that human error can happen while measuring cargo dimensions. Let’s say that, due to manual measurement or another imperfect measuring system, a pallet is measured as 40 in. x 40 in. x 40 in.—just a one-inch error (or less) for length, width, and height. Not much of an error, right? The problem is that the new volume now is 64,000 cubic inches, nearly 3,000 cubic inches OVER our actual total.

Assuming 15 such pallets are shipped per week using the mistaken measurement, the volume numbers add up as follows:

- Actual dimensions: 15 x 39 in. x 39 in. x 39 in. = 915,355 cubic inches

- With error: (15 x 40 in. x 40 in. x 40 in. = 960,000 cubic inches

That’s almost 45,000 cubic inches off our real dimensions! As you can imagine, the unnecessary costs add up fast. The additional costs due to the inefficiency are as follows:

For LCL Shipping:

- $36 weekly

- $144 monthly

- $1,728 annually

For Air Freight Shipping:

- $58 weekly

- $232 monthly

- $2,784 annually

Remember, that’s with only 15 pallet dimensioning errors each week. Many of our clients ship many more than that! Those are real costs that can mean the difference between quarterly profit and loss, in some cases.

That’s why Cargo Spectre believes that every inch counts. Every cubic inch costs money in shipping! In order to avoid such costly mistakes from occurring again and again, we engineered a simple, easy-to-use dimensioning solution that protects our clients from overpaying for pallet shipping.

Using depth sensors, our Pallet Spectre pallet dimensioner can measure and record every detail of your palletized freight instantly. Bulging freight, uneven or leaning pallets, and even damaged freight scanned by our system will not affect Cargo Spectre’s ability to deliver a max cube every time. Each Pallet Spectre dimensioner is capable of dimensioning, weighing, and photographing any pallet or object in just seconds.

Best of all, the hardware for a Cargo Spectre automated dimensioning system costs less than our competitors’ and can be set up in as little as one hour. We’re able to offer the same or better NTEP-certified performance as dimensioning systems that cost ten times more than ours! It’s an incredible savings that has made Cargo Spectre the world’s fastest-growing cargo dimensioning solution in the world.

If you’re ready to ensure that human error in dimensioning never costs your business another penny, contact us today. Our warehouse and shipping experts are standing by to provide a free consultation on your dimensioning needs!